Sintered Wire Mesh is a standard lamination structure made by sintering multi-layers of stainless steel wire cloth together through vacuum processing. Involved processing includes vacuum sinter, compression and rolling and fabricating. Sintered metal is a kind of porous metal sheet with wide applications. Commonly three or five layers are applied in manufacture of sintered mesh. Tejido can supply sintered wire mesh laminates and its finished filter cartridges and elements products.

Compared with woven wire filter cloth, the sintered metal mesh has two apparent benefits:

One is that sintered mesh has strong and solid structure; the other is that the sintered laminate is easier to be fabricated than single layer woven wire mesh into filter elements of various shapes without breaking of wires. It can be processed into filter elements in round, barrel and conic shape.

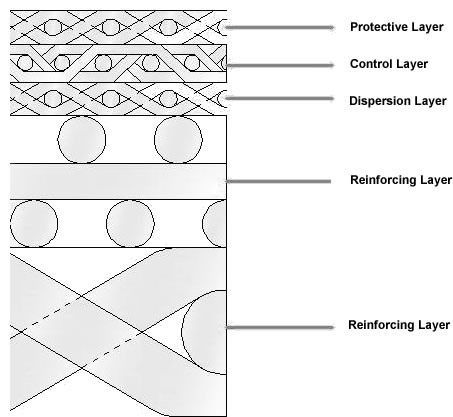

Take five layer sintered mesh as example, the standard five layer sintered wire mesh structures are as follows:

Two reinforcing layer;

one dispersing layer;

one filter control layer;

one protective layer.

General Information:

Materials:SS304,SS316,SS316L

Standard Sintered Mesh Size:500x1000mm; 600x1200mm. Max size: 610mmx1250mm

Features:

Sintered mesh has the superior advantage of fine micron opening (from 1micron to 100micron), high durability, high strength, easy to wash than the other filter materials.

· Constant filter rating: with protective layers and sintering combination technology, the mesh of the filter layer is not easy to change.

· High mechanical strength. Excellent resistance to pressure and high mechanical strength thanks to the fourth and fifth metal layers reinforced.

· Corrosion resistance as a result of adopting choice 316L.

· High accuracy: Outstanding filtration performance can be achieved thanks to the precise aperture of the control layer, also the good function of dispersion layer.

· Heat resistance. Heat resistant up to 480℃.

· Easy processing: The sintered metal sheet is suitable to cut, punching, warp tension and jointing.

· Easy Washing: Especially back washing owing to the surface filtration structure.

| Sintered Mesh Main Data | ||||||

| Absolute Filtration Rating (μm) |

Bubble Pressure (Pa) |

Average Air Density (1/dm2/min) |

Thickness (mm) |

Weight (g/m2) |

Porosity (%) |

Dirt Holding (mg/cm2) |

| 3 | 12300 | 9 | 0.35 | 975 | 65 | 6.40 |

| 5 | 7600 | 34 | 0.34 | 600 | 78 | 5.47 |

| 7 | 5045 | 57 | 0.27 | 600 | 72 | 6.47 |

| 10 | 3700 | 100 | 0.32 | 600 | 77 | 7.56 |

| 15 | 2470 | 175 | 0.37 | 600 | 80 | 7.92 |

| 20 | 1850 | 255 | 0.49 | 750 | 81 | 12.44 |

| 25 | 1480 | 320 | 0.61 | 1050 | 79 | 19.38 |

| 30 | 1235 | 455 | 0.63 | 1050 | 79 | 23.07 |

| 40 | 925 | 580 | 0.66 | 1200 | 77 | 25.96 |

| 60 | 630 | 1000 | 0.70 | 750 | 87 | 33.97 |

| Technical Data of Sintered Mesh: | ||||||

| Nominal Filtration Rating (μm) |

Control Layer (mesh) |

Air Permeability (%) |

Resistance (cm) |

Initial Bubble Pressure (mm H2o) |

Thickness (mm) |

Weight (kg/m2) |

| 2 | 325x2400 | 38 | 14x105 | 280-640 | 1.7 | 8.4 |

| 5 | 200x1400 | 38 | 12x105 | 250-600 | 1.7 | 8.4 |

| 10 | 165x1400 | 38 | 7x105 | 220-550 | 1.7 | 8.4 |

| 20 | 165x800 | 38 | 4x105 | 180-450 | 1.7 | 8.4 |

| 40 | 50x250 | 38 | 4x105 | 150-400 | 1.7 | 8.4 |