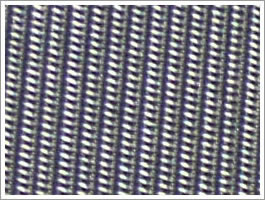

Weaving Method: Reverse Dutch weave is applied for optimizing filtering media manufacture thanks to a high percentage crossing/opening surface. By varying the combination of weft and warp wires, filtering ratings from 14 to 100 microns can be obtained, with an available crossing or opening surface of 30-40%, the maximum yield in similar conditions.

Weaving Method: Reverse Dutch weave is applied for optimizing filtering media manufacture thanks to a high percentage crossing/opening surface. By varying the combination of weft and warp wires, filtering ratings from 14 to 100 microns can be obtained, with an available crossing or opening surface of 30-40%, the maximum yield in similar conditions.

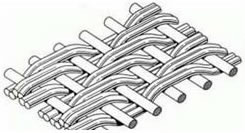

The apparent difference of Reverse Dutch Weaving compared with standard Dutch weave lies in the thicker warp wires and less weft wires.

Compared with square hole woven wire mesh, Dutch Reverse Wire Mesh (actually all the Dutch woven wire mesh) has an improved mesh thickness, filteration precision and service life. The warp wire, weft wire and density have great contrast which enables an excellent filteration under strains and pressure.

Features of Stainless Steel Wire Mesh Reverse Dutch Weave:

Acid proof, alkali proof, high temperature resistance, high resistance to wear, fine iltering performance, high precision,etc.

Advantages of Reverse Dutch Woven Wire Cloth:

1. Continuous work, no need stop for work, save time, save labor

2. Applicable in a variety of extruders as filter screen

3. Constant melt pressure to ensure the best quality products

4. Applicable to a variety of materials, such as PP, HDPE, LDPE, PS, etc.

5. Very long service life.

6. Easy to operate.

Material for Weaving:

High quality stainless steel wire: 302-304.

Uses:

Reverse Dutch woven wire is widely processed as extruder screen in plastics, chemical fiber,rubber and other industries as solution of the solid particle filtering and screening.

General Technical Information:

Mesh:From 5x40mesh to 325x2300mesh

Roll

Width:1-2m( Can be changed according to require )

Roll

Length:Generally is 30 meters( Can be changed ).

Specification of Reverse Dutch Weave Wire Mesh in Stainless Steel:

| Mesh Count Warp x Weft |

Wire Dia mm Warp x Weft |

Wire Dia inch Warp x Weft |

Open Area % |

Micron Rating |

| 63 x 18 | 0.4000 x 0.6000 | 0.0157 x 0.0236 | 60 | 220 |

| 107 x 20 | 0.2400 x 0.6000 | 0.0094 x 0.0236 | 58 | 210 |

| 170 x 40 | 0.2000 x 0.4500 | 0.0079 x 0.0177 | 58 | 130 |

| 132 x 32 | 0.2000 x 0.4000 | 0.0079 x 0.0157 | 55 | 105 |

| 171 x 46 | 0.1500 x 0.3000 | 0.0059 x 0.0118 | 54 | 85 |

| 290 x 75 | 0.0900 x 0.2000 | 0.0035 x 0.0079 | 53 | 55 |

| 615 x 102 | 0.0400 x 0.1600 | 0.0157 x 0.0063 | 41 | 42 |

| 615 x 130 | 0.0400 x 0.1300 | 0.0157 x 0.0051 | 49 | 22 |

| 720 x 150 | 0.0360 x 0.1000 | 0.0014 x 0.0039 | 54 | 17 |